Blog

by

The Inspiring Journey

Innovative Materials in Manufacturing:

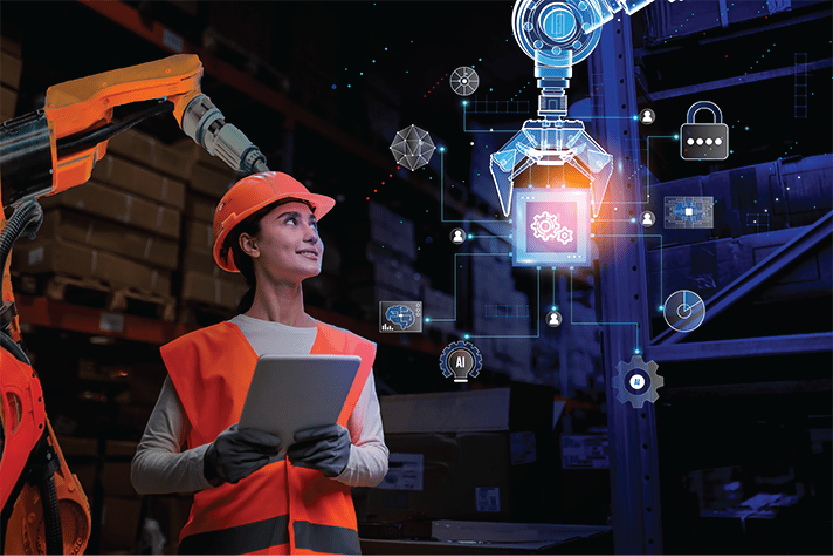

Innovative materials have become a driving force in the evolution of the manufacturing industry, heralding a new era of possibilities and advancements. This article delves into the transformative impact of innovative materials, exploring their role in reshaping manufacturing processes, enhancing product innovation, and driving sustainable practices.

The Rise of Innovative Materials

The manufacturing industry is witnessing a paradigm shift fueled by the emergence of innovative materials. From advanced composites and biodegradable polymers to smart textiles and sustainable alloys, these materials are redefining the boundaries of manufacturing capabilities. Their unique properties, including lightweight construction, enhanced durability, and environmental sustainability, are opening doors to a myriad of applications across diverse sectors, from aerospace and automotive to consumer electronics and healthcare.

Integrating Innovative Materials

Incorporating innovative materials into manufacturing processes is revolutionizing production methods and product design. Additive manufacturing technologies, such as 3D printing, are enabling the seamless integration of advanced materials, allowing for intricate geometries, rapid prototyping, and customized components. Furthermore, the compatibility of innovative materials with digital manufacturing tools, such as Computer-Aided Design (CAD) and simulation software, is fostering a culture of continuous innovation and product customization, propelling the industry towards new frontiers of creativity and efficiency.

Sustainability at the Core:

Innovative materials are at the forefront of driving sustainability and environmental responsibility within the manufacturing industry. With a focus on recyclability, bio-based sourcing, and reduced carbon footprint, these materials are aligning with the imperatives of sustainable manufacturing practices. By leveraging innovative materials, manufacturers are not only enhancing the environmental profile of their products but also contributing to the broader goal of creating a circular economy, where materials are reused, repurposed, and recycled to minimize waste and environmental impact.

The Future of Innovative Materials in Manufacturing

As the manufacturing industry continues to embrace the potential of innovative materials, the horizon is brimming with possibilities. From self-healing polymers and nanomaterials to bio-inspired composites and smart textiles, the trajectory of innovative materials is poised to redefine the very fabric of manufacturing. This evolution will not only drive product innovation and performance but also pave the way for sustainable, resource-efficient manufacturing practices, shaping a future where materials are the catalysts for transformative change.

Accepting Innovation in Materials

The infusion of innovative materials into the manufacturing industry represents a pivotal moment in its evolution. These materials are not only expanding the realm of possibilities for product design and performance but also driving a fundamental shift towards sustainable, environmentally conscious manufacturing practices. As the industry looks to the future, it is clear that innovative materials will continue to be a cornerstone of progress, fueling creativity, efficiency, and sustainability in the manufacturing landscape